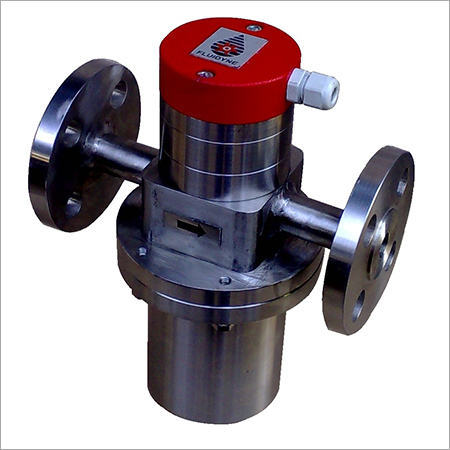

Chemical Flow Meter

Chemical Flow Meter Specification

- Measurement Range

- 1 LPH to 24000 LPH

- Connectivity Type

- 4-20mA / RS485 MODBUS

- Pressure Range

- Up to 16 bar

- Humidity %

- Max 95% RH, non-condensing

- Flow Rate

- 1 LPH to 24000 LPH

- Equipment Type

- Chemical Flow Meter

- Temperature Range

- 0C to 60C

- Resolution

- 0.1 LPH

- Frequency

- 50/60 Hz

- Capacity

- Up to 24000 LPH

- Current Range

- 4-20mA

- Sensor Type

- Electromagnetic/Ultrasonic

- Material

- S.S and Plastics

- Power Supply

- 24V DC / 230V AC

- Product Type

- Flow Meter

- Power Consumption

- < 10W

- Accuracy

- +/- 0.5 %

- Display Type

- Flameproof / Weather Proof

- Range

- 1 LPH to 24000 LPH

- Display Features

- Totalizer, Instantaneous Value, Flow Direction

- Cable Entry

- Double Compression Gland

- Power Backup

- Optional

- Communication

- Optional HART/Profibus

- Compliance

- CE Marked

- Ingress Protection

- IP65 / IP67

- Process Connection

- Flanged / Threaded

- Mounting

- Inline, Flange Type

- Output Signal

- Pulse / 4-20mA / RS485

- Suitable for

- Corrosive & Non-corrosive Chemicals

- Enclosure Material

- Aluminium Die Cast / Plastic

Chemical Flow Meter Trade Information

- Minimum Order Quantity

- 5 Units

- Supply Ability

- 50 Units Per Month

- Delivery Time

- 1-5 Months

- Main Domestic Market

- All India

About Chemical Flow Meter

We are a reliable enterprise, successfully engaged in manufacturing, exporting and supplying the best quality Chemical Flow Meter. Widely used for the measurement of corrosive and non-corrosive chemicals, this meter finds application in water treatment, chemical processing, pharmaceutical and other related industries. Also, tested by quality professionals on several aspects, the offered Chemical Flow Meter can be purchased at economic prices from us.Specifications:

- All SS 316 / Ptfe construction.

- Compatible with all corrosive / non corrosive chemicals.

- Available in 1/4" to 3" Line Size 1 LPH to 24000 LPH flow range.

- Display Transmitter in Flameproof / Weather Proof construction.

- Accuracy +/- 0.5% of reading guaranteed for very low to very high viscous liquids.

- Choice of Pulse output / Analog 4-20 mA output / RS485 Modbus Serial Output

Key Points:

- Require less maintenance

- Optimum performance

- Power efficient

- Long life

- Continuous measurement of corrosive and noncorrosive chemicals.

- Batching of solvents to Reactors in bulk drug manufacturing.

- Dosing of aggressive acids in water treatment plants.

- Batch control in chemical automation system.

- Ratio mixing of liquids such as Alcohol, Water, Ethylene Glycol, etc.

Product details

| Display Type | Digital |

| Material | Stainless Steel |

| Voltage | 220 V |

| Frequency | 50 Hz |

| Flow Range | 24000 LPH |

| Accuracy | +-0.5% |

| Application Media | Chemical |

| Brand | Fluidyne |

Versatility for Challenging Chemical Environments

This flow meter is suitable for measuring a wide range of chemicals, whether corrosive or non-corrosive. Its rugged enclosure options, made from aluminium die-cast or plastic, combined with high ingress protection ratings (IP65/IP67), make it reliable in harsh or hazardous industrial settings. The meters material compatibility, including stainless steel and plastics, extends its usability across various industries.

Flexible Installation and Comprehensive Output Options

Offering both inline and flange-type mounting, with flanged or threaded process connections, this meter can be smoothly incorporated into new or existing systems. Communication and signal output flexibilityPulse, 4-20mA, RS485 MODBUS, and optional HART/Profibusensures compatibility with diverse automation and monitoring setups. These features streamline process integration and data collection.

Accurate Measurement and User-Friendly Display

With a measurement range from 1 LPH to 24,000 LPH, a resolution of 0.1 LPH, and an accuracy of 0.5%, users benefit from precise flow data. The user interface displays totalized flow, real-time values, and flow direction. Optional power backup supports continuous operation, while flameproof or weatherproof display options provide safety and performance confidence in demanding environments.

FAQs of Chemical Flow Meter:

Q: How does the Chemical Flow Meter ensure compatibility with different chemicals and installation environments?

A: The meter is constructed from resistant materials such as stainless steel and plastics, making it suitable for corrosive and non-corrosive chemicals. Ingress protection ratings (IP65/IP67) and enclosure options like aluminium die-cast or plastic provide durability in harsh industrial settings.Q: What display features are provided for monitoring flow data?

A: The meters display shows important parameters including totalized flow, instantaneous value, and flow direction. Depending on the application needs, customers can choose between flameproof or weatherproof display types for reliable real-time monitoring.Q: When is power backup recommended for this flow meter?

A: Power backup is recommended if there is a risk of power interruptions, as it enables uninterrupted measurement and data logging, ensuring critical flow data is not lost during outages.Q: Where can this flow meter be installed, and what mounting types are available?

A: It can be installed in any process line that carries chemicals within its specified flow, pressure, and temperature ranges. It supports inline and flange-style mounting, with process connections available as flanged or threadedallowing for versatile installation options.Q: What is the process for integrating this meter with existing automation systems?

A: Integration is straightforward due to its multiple output signal options (Pulse, 4-20mA, RS485 MODBUS) and optional communication protocols like HART or Profibus. This flexibility ensures compatibility with a variety of control and SCADA systems.Q: How is the flow meter beneficial for precise chemical flow monitoring?

A: The meter provides high accuracy of 0.5% and a resolution of 0.1 LPH, supporting precise measurement across a wide flow range. This helps maintain process control, ensures safety, and optimizes chemical usage in industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Flow Meter Category

Diesel Flow Meter

Price Range 15000.00 - 150000.00 INR / Unit

Minimum Order Quantity : 5 Units

Accuracy : + 0.5% %

Display Type : Other, Digital

Range : 0.6 24000 LPH

Product Type : Diesel Flow Meter

Flow Transmitter

Price Range 15000.00 - 150000.00 INR / Unit

Minimum Order Quantity : 5 Units

Accuracy : 0.5 %

Display Type : Digital Only

Range : 624000 LPH

Product Type : Flow Transmitters

Oil Flow Meter

Price Range 15000.00 - 150000.00 INR / Unit

Minimum Order Quantity : 5 Units

Accuracy : +/ 0.5% +/ 0.1 %

Display Type : Analog And Digital

Range : 1.0 LPH to 24000 LPH.

Product Type : Oil Flow Meter

Rotary Piston Flow Meter

Minimum Order Quantity : 5 Units

Accuracy : +/ 0.5 % of 0.1 % %

Display Type : Other

Range : 1.0 LPH to 24000

Product Type : Piston Flow Meter

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free