Diesel Flow Meter

Diesel Flow Meter Specification

- Humidity %

- Up to 95% RH (Non-condensing)

- Temperature Range

- -10C to 60C

- Measurement Range

- 0.6 - 24000 LPH

- Pressure Range

- Up to 10 Bar

- Resolution

- 0.01 Litre

- Capacity

- Up to 24,000 LPH

- Flow Rate

- 0.6 - 24,000 LPH

- Connectivity Type

- Local / Optional Remote Output

- Sensor Type

- Turbine / Oval Gear Sensor (as per model)

- Material

- S.S and Plastics

- Power Supply

- Battery Operated / External Power Supply (as required)

- Power Consumption

- Low (depends on display type)

- Product Type

- Diesel Flow Meter

- Accuracy

- + 0.5% %

- Color

- Silver

- Display Type

- Digital

- Range

- 0.6 - 24000 LPH

- Application

- Industrial / Commercial Fuel Measurement

- Connection Size

- 1" BSP / NPT (Other sizes available)

- Output Signal

- Pulse / 4-20 mA (Optional)

- Equipment Type

- Diesel Flow Meter

- Ingress Protection

- IP65

- Applicable Fluids

- Diesel, Oil, Kerosene

- Service Life

- >1 Million Litres (typical)

- Mounting

- Inline / Wall Mounted

- Operating Voltage

- 3V / 9V / 12V DC (Model Dependent)

- Weight

- Approx. 1.2 - 2.3 kg (depends on model)

Diesel Flow Meter Trade Information

- Minimum Order Quantity

- 5 Units

- Supply Ability

- 50 Units Per Month

- Delivery Time

- 1-5 Months

- Main Domestic Market

- All India

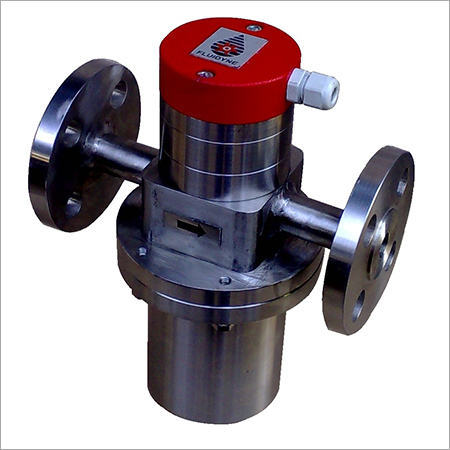

About Diesel Flow Meter

The diesel flow meter is widely used for the measurement of unloaded diesel from tanker. It is available in 1/4" to 3" line size. The flow range of the meter ranges from 1.0 LPH to 24000 LPH. It is lightweight and is made of cost-effective aluminum alloys. The accuracy of the meter is +/- 0.5% of reading and repeatability of 0.1% of reading. The meter has electronic digital display with weatherproof and flameproof enclosure. The retransmission output of analog 4 to 20 mA. The digital flow meter is applied for the measurement of diesel transfer from bulk tank to respective tank.

Key Points:

- Robust construction

- Longer service life

- Accurate measurement

- Easy to operatin

Specifications:

- Available in 1/4" to 3" Line Size.

- Flow Range from 1.0 LPH to 24000 LPH.

- Light weight and economical aluminum alloys construction.

- Accuracy +/- 0.5% of reading and repeatability of 0.1% of reading.

- Electronic digital display with Flameproof and Weatherproof enclosure.

- Retransmission output of analog 4-20mA or RS485 Modbus Serial.

Product details

| Output Signal | 20 mA |

| Material | Stainless Steel |

| Accuracy | +/- 0.5% of Reading |

| Line Size | 3" |

| Application Media | Water |

| Brand | Fluidyne |

| Display | Digital |

| Flow range | 24000 LPH |

Versatile Installation Options

The meter can be mounted inline or on walls, catering to diverse setup requirements in factories or commercial fuel dispensing stations. Connection sizes start at 1" BSP/NPT, but other sizes are available to suit specific pipework and system configurations.

Advanced Measurement Technology

Choose from turbine or oval gear sensors depending on your application needs. The meter delivers accurate measurements with a resolution of 0.01 litre within an operating range from 0.6 to 24,000 LPH, making it suitable for both low and high flow rates.

Durable and Adaptable Design

Constructed with stainless steel and plastics, the meter withstands challenging environments. It operates efficiently within a temperature range of -10C to 60C and high humidity, ensuring durability and reliable service life exceeding one million litres.

FAQs of Diesel Flow Meter:

Q: How is the Diesel Flow Meter installed in industrial environments?

A: The Diesel Flow Meter supports both inline and wall-mounted installation. You can choose the appropriate configuration based on your pipeline setup or wall space, and select the suitable connection size (typically 1 BSP/NPT) for secure integration.Q: What types of fluids can the flow meter accurately measure?

A: This flow meter is designed to measure diesel, oil, and kerosene. Its robust build and accurate sensors ensure reliable performance with these fuels in industrial and commercial applications.Q: When should the flow meter be calibrated and maintained?

A: Calibration frequency depends on application intensity and local industry standards. Generally, periodic checks ensure sustained accuracy. The meters typical service life exceeds one million litres, making routine maintenance efficient and cost-effective.Q: Where can the flow meter be used?

A: It is suitable for installation in industrial plants, fuel stations, and commercial sites where monitoring of diesel, oil, or kerosene consumption is required. Its IP65 rating allows operation even in harsh environments with high humidity and dust.Q: What are the output signals available, and how are they used?

A: The meter can provide pulse or optional 4-20 mA output signals, which can be connected locally to controllers or remotely to monitoring systems, supporting effective process automation and data logging.Q: How does the digital display benefit fuel measurement?

A: The digital display provides clear, instant readings with a fine resolution of 0.01 litre, enabling users to monitor fuel usage accurately and efficiently at a glance.Q: What power options are supported by the flow meter?

A: The meter accommodates both battery operation and external power supply, with operating voltages of 3V, 9V, or 12V DC, depending on the model. This flexibility ensures compatibility with a variety of installation scenarios.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Flow Meter Category

Chemical Flow Meter

Price Range 15000.00 - 150000.00 INR / Unit

Minimum Order Quantity : 5 Units

Product Type : Flow Meter

Display Type : Flameproof / Weather Proof, Other

Accuracy : +/ 0.5 %

Range : 1 LPH to 24000 LPH

Flow Transmitter

Price Range 15000.00 - 150000.00 INR / Unit

Minimum Order Quantity : 5 Units

Product Type : Flow Transmitters

Display Type : Digital Only

Accuracy : 0.5 %

Range : 624000 LPH

Oil Flow Meter

Price Range 15000.00 - 150000.00 INR / Unit

Minimum Order Quantity : 5 Units

Product Type : Oil Flow Meter

Display Type : Analog And Digital

Accuracy : +/ 0.5% +/ 0.1 %

Range : 1.0 LPH to 24000 LPH.

Digital Flow Meter

Price Range 15000.00 - 150000.00 INR / Unit

Minimum Order Quantity : 5 Units

Product Type : Digital Flow Meter

Display Type : digital display with Flame proof and Weatherproof enclosures, Other

Accuracy : +/ 0.5 % of 0.1 % %

Range : 1.0 LPH to 24000 LPH

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free