Positive Displacement Flow Meter

Positive Displacement Flow Meter Specification

- Material

- S.S and Plastics

- Product Type

- Flow Meter

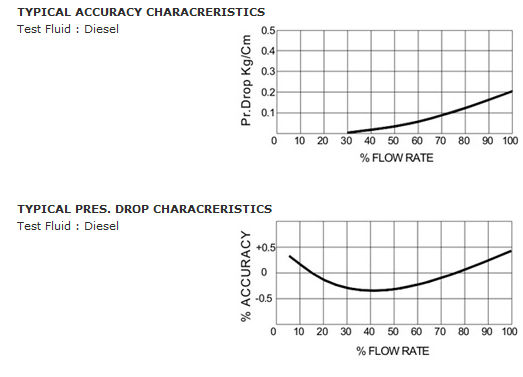

- Accuracy

- +/- 0.5 %

- Color

- Grey

- Display Type

- Digital Only

- Range

- 3.0 to 24000 LPH

Positive Displacement Flow Meter Trade Information

- Minimum Order Quantity

- 5 Units

- Supply Ability

- 50 Units Per Month

- Delivery Time

- 1-5 Months

- Main Domestic Market

- All India

About Positive Displacement Flow Meter

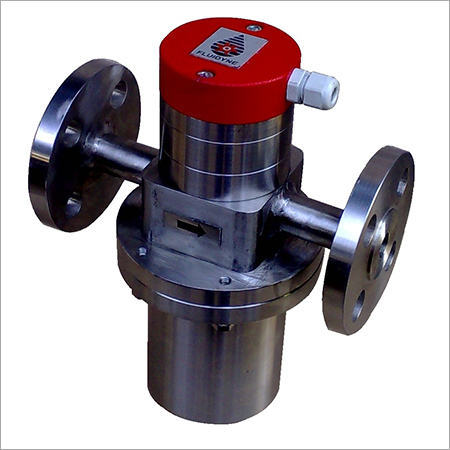

We are regarded as one of the topmost brand offering wide assortment of Fluidyne Positive Displacement Flow metres that is based on the time tested Oscillating Piston design. A single moving component in the assembly ensures extremely reliable operation for long period of operation. Use of state of the art solid state magnetic sensor, ultra low powered electronic sensor provides for all the simplicity of a mechanical positive displacement flow meter and the reliability of electronic sensing and read outs. Our flow metre is fabricated using quality raw material procured from reliable sources. We offer best deals at really affordable prices.Applications:

For Fuels / Solvents / Chemicals / Lube Oils.

Features:

- Wide operating flow range of 3.0 to 24000 LPH

- Guaranteed accuracy of +/- 0.5% of reading

- Low pressure drop allows gravity head operation.

- Operation at maximum 1500 C temperature possible.

- Self powered electronics ensures fit and forget operation.

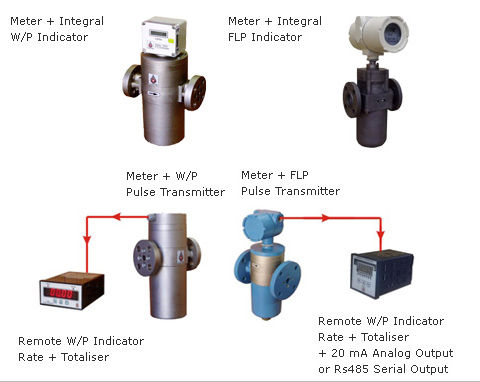

- Choice of weatherproof and flame proof electronic enclosures.

- Built in high capacity reusable wire mesh filter.

- S.S and Plastics builds to suit corrosive liquids.

- Available in 1A to 3 Line Size.

- Flow Range for 1.0 LPH to 24000 LPH liquid temperature up to 150C.

- Precision measurement of low and high viscosity corrosive/ non corrosive liquids.

- Accuracy +/- 0.5 % of reading. Repeatability +/- 0.1 % of reading.

- Electronic digital display with Flame proof and Weatherproof enclosures.

- Externally powered and self powered options.

Applications:

- Precision measurement of Fuels, Lube Oils, Solvents, Chemicals.

- Accurate measurement of Ro and Dematerialized water.

- High temperature measurement of hot FO, HFO and LSHS.

- Precision measurement of hydro carbons and organic liquids.

- Precision measurement of very low flow up to 1.0 LPH.

Technical Specifications:

Size DN 06 / 15 / 20 / 25 / 40 / 50 / 80 Flow Accuracy 3.0 - 24000 LPH Accuracy + 0.5% of reading Repeatability + 0.1% of reading Operating Pressure 10 Kg / Cm2 Max. Operating Temperature 1500 C Filter Mesh Size 150 Micron SS Mesh Reusable Type Read Out Option

- Self Powered Totaliser

- Rate Indicator Totaliser

- Rate Indicator Totaliser + 4 - 20 mA output

- Rate Indicator Totaliser + RS485 Serial Output

Flange : ANSI / BS / DIN End Connections Screw : BSP / NPT Female Threads

Wetted Parts : Aluminium / SS 316 / PVCMaterial of construction Piston : PEEK / PVC

Seals : BUNA N / Viton / EPDM / PTFE

Size Vs Flowrange Table:

Flow Meter Size NB Operating Flow Range LPH DN06 3-60 DN15 60-600 DN20 150-1500 DN25 240-2400 DN40 600-6000 DN50 1200-12000 DN80 2400-2400

Application:

Accurate Measurement and Versatility

This Positive Displacement Flow Meter is engineered for accuracy with an excellent tolerance of +/- 0.5%. Its wide measuring rangefrom 3.0 to 24,000 liters per hourmakes it suitable for diverse flow monitoring needs, from small-scale to large-volume applications. The meters precision helps industries maintain quality standards and optimize operational efficiency.

Durable Construction and User-Friendly Display

Built with stainless steel and plastic materials, the meter resists corrosion and withstands harsh process environments. Its digital-only display simplifies usage, allowing operators to quickly access real-time flow data without hassle. The modern grey design complements contemporary industrial settings while ensuring long-lasting performance.

Trusted Supplier from India

As a prominent exporter, manufacturer, and supplier, we serve clients in India and abroad. Our products adhere to stringent quality standards, and our reliable after-sales support ensures customer satisfaction throughout the products lifecycle.

FAQs of Positive Displacement Flow Meter:

Q: How does a Positive Displacement Flow Meter work?

A: A Positive Displacement Flow Meter measures fluid flow by capturing fixed volumes of liquid within its chamber, then counting the number of times the chamber fills and empties to determine the total flow rate. This method provides highly accurate readings, even with viscous or low-flow fluids.Q: What is the measuring range and accuracy of this meter?

A: The meter covers a flow range of 3.0 to 24,000 liters per hour, offering exceptional versatility for a wide range of applications. Its accuracy is within +/- 0.5%, making it ideal for processes where precise measurement is crucial.Q: Where can this flow meter be installed?

A: This flow meter is suitable for installation in industrial, commercial, and laboratory settings, especially where chemically resistant materials and robust construction are required. Its compact design and versatile mounting options allow easy integration into various piping systems.Q: What materials are used in the construction of this meter?

A: The flow meter is manufactured using high-quality stainless steel and plastics, offering excellent durability and resistance to most chemicals. The combination ensures reliable performance in demanding process conditions.Q: How do I read and monitor flow data with this device?

A: This meter is equipped with a digital-only display, providing clear and accurate real-time data. Operators can easily read flow rates and totals at a glance, streamlining monitoring and process control tasks.Q: What are the key benefits of using this flow meter?

A: Key benefits include its high accuracy, wide measuring range, robust construction, and ease of use. These features help reduce product losses, ensure process consistency, and minimize maintenance downtime, contributing to improved operational efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Flow Meter Category

Chemical Flow Meter

Price Range 15000.00 - 150000.00 INR / Unit

Minimum Order Quantity : 5 Units

Accuracy : +/ 0.5 %

Range : 1 LPH to 24000 LPH

Product Type : Flow Meter

Display Type : Flameproof / Weather Proof, Other

Diesel Flow Meter

Price Range 15000.00 - 150000.00 INR / Unit

Minimum Order Quantity : 5 Units

Accuracy : + 0.5% %

Range : 0.6 24000 LPH

Product Type : Diesel Flow Meter

Display Type : Other, Digital

Flow Transmitter

Price Range 15000.00 - 150000.00 INR / Unit

Minimum Order Quantity : 5 Units

Accuracy : 0.5 %

Range : 624000 LPH

Product Type : Flow Transmitters

Display Type : Digital Only

Oil Flow Meter

Price Range 15000.00 - 150000.00 INR / Unit

Minimum Order Quantity : 5 Units

Accuracy : +/ 0.5% +/ 0.1 %

Range : 1.0 LPH to 24000 LPH.

Product Type : Oil Flow Meter

Display Type : Analog And Digital

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese